From straight-run naphtha

to straight-up profit

Obstacle

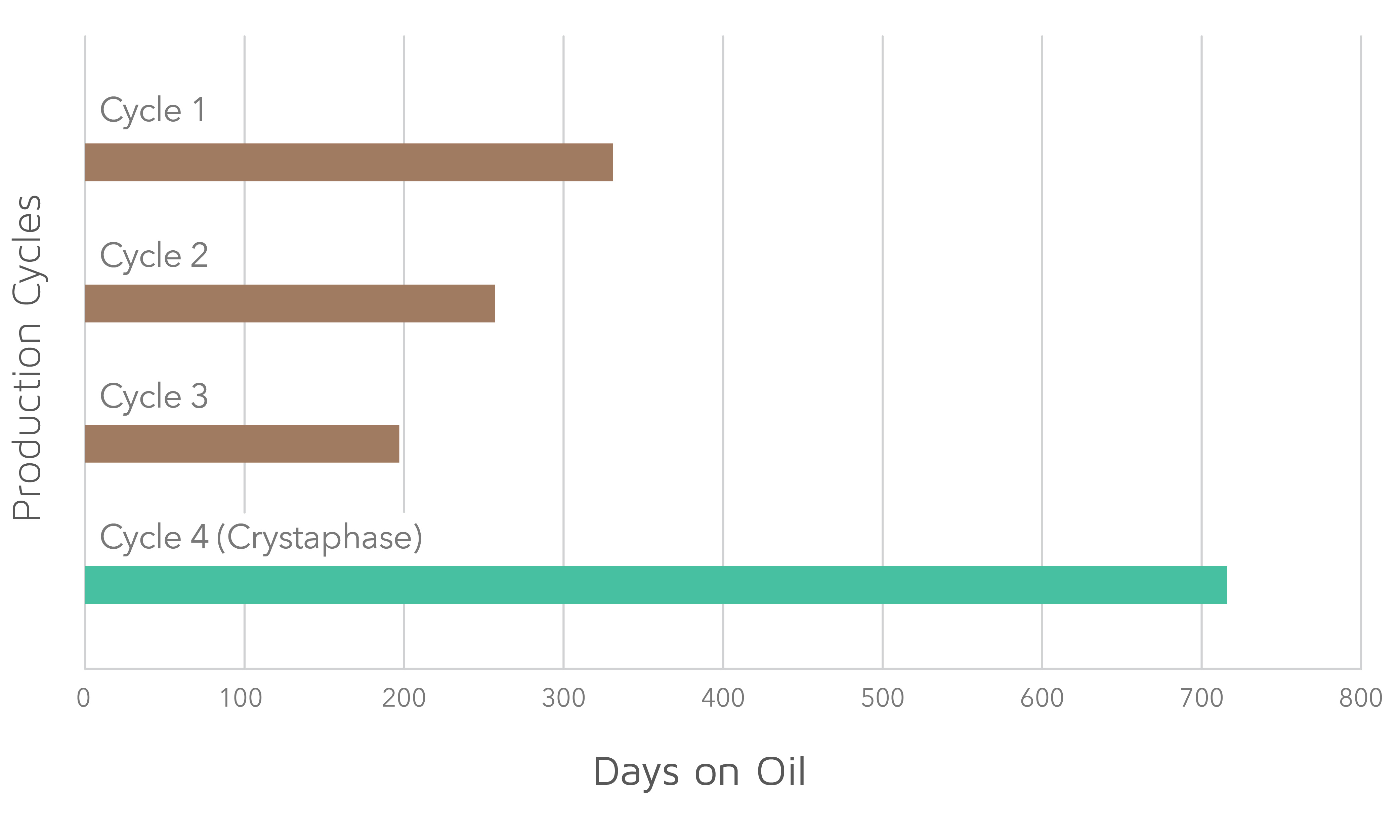

Straight-run naphtha is usually an easy feed to process. Engineers like it because no additives are required—no free radicals turning into foulants. In this case however, our customer was facing increasingly shorter production cycles, running 331 days on oil, then 257 days, then 197 days before a pressure-drop shut down was required.

Path

They called Crystaphase. We recommended replacing 180 cubic feet of conventional wagon wheels and rings with a custom CatTrap® solution that used only 159 cubic feet.

Results

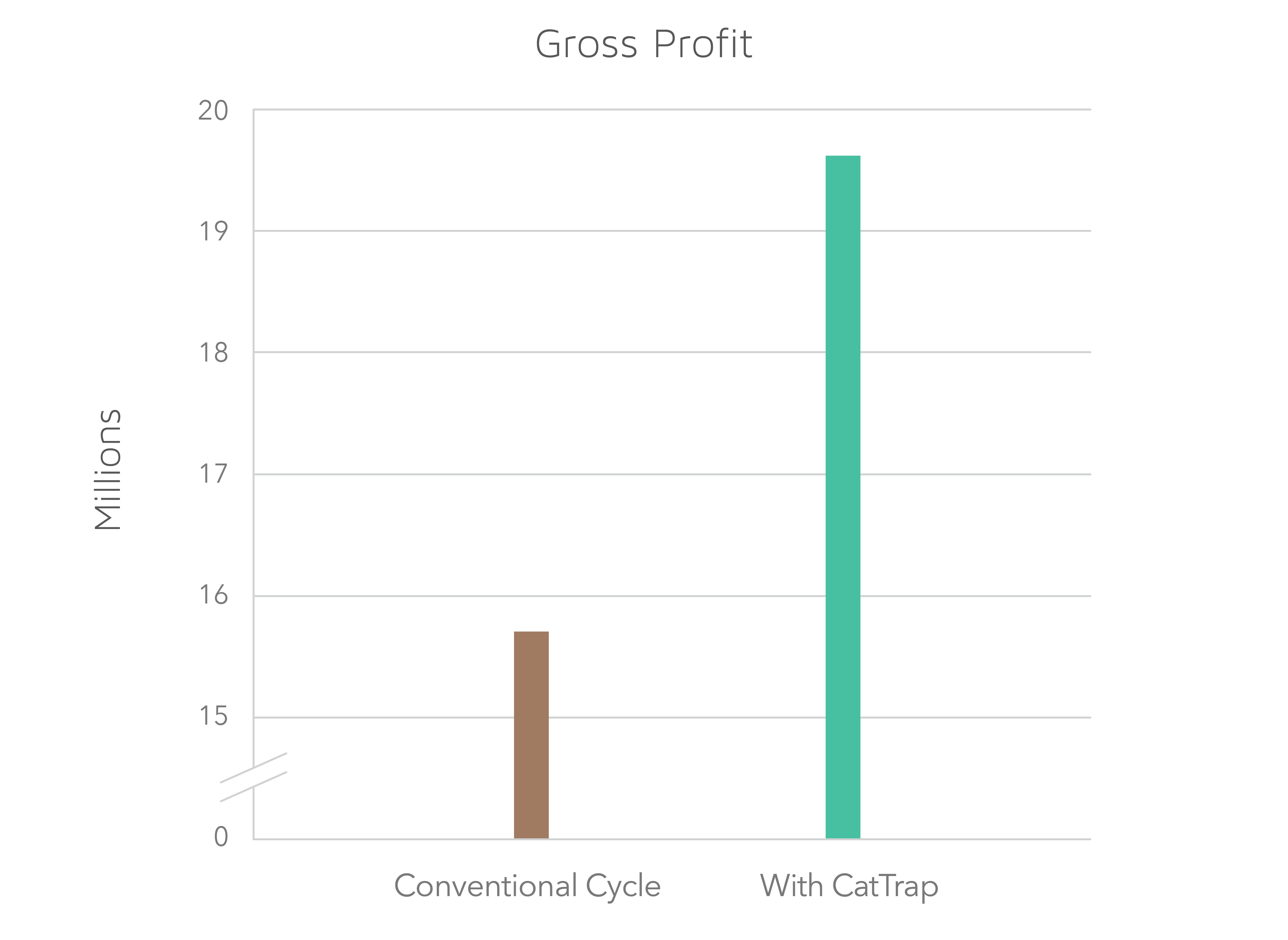

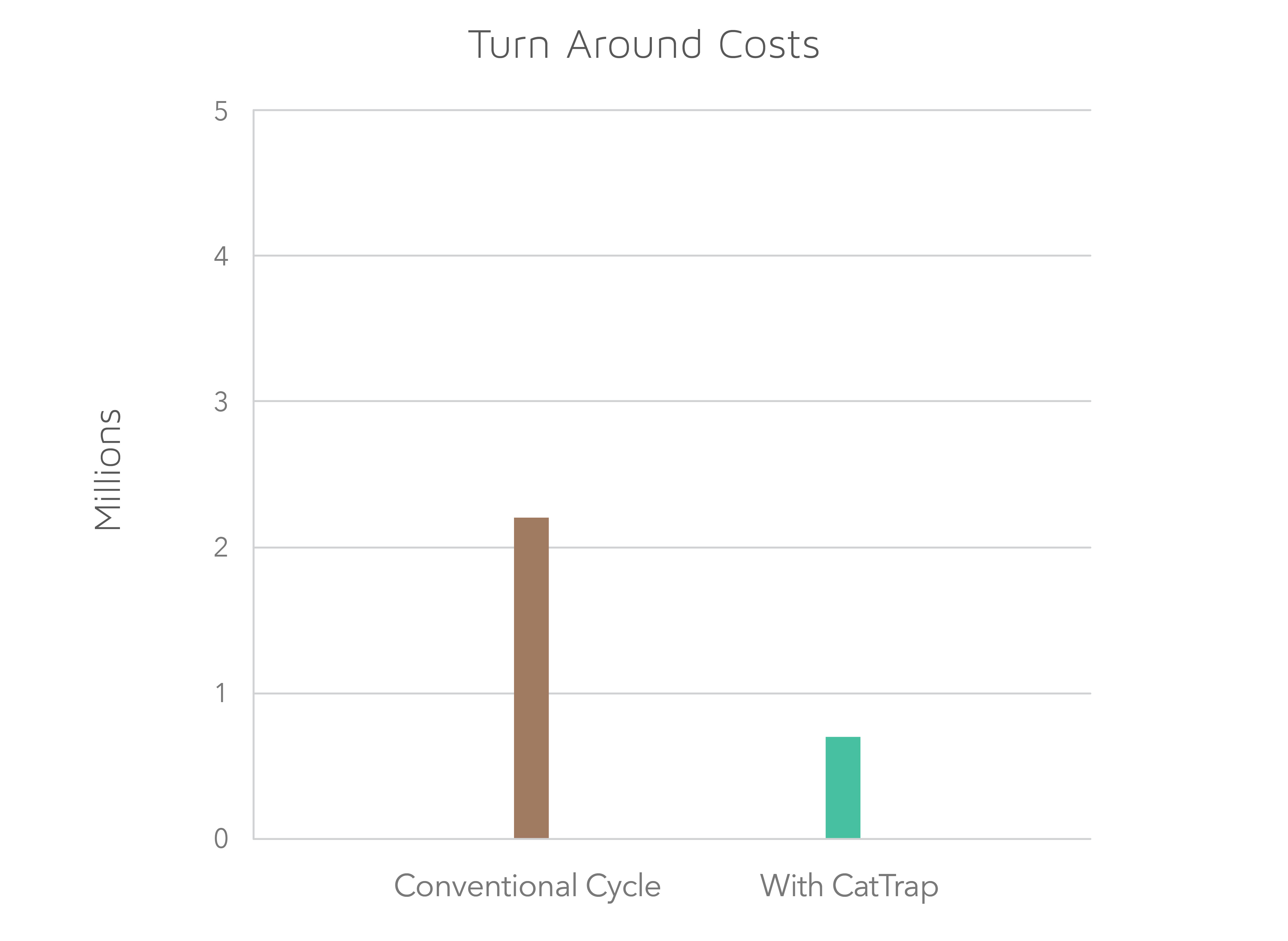

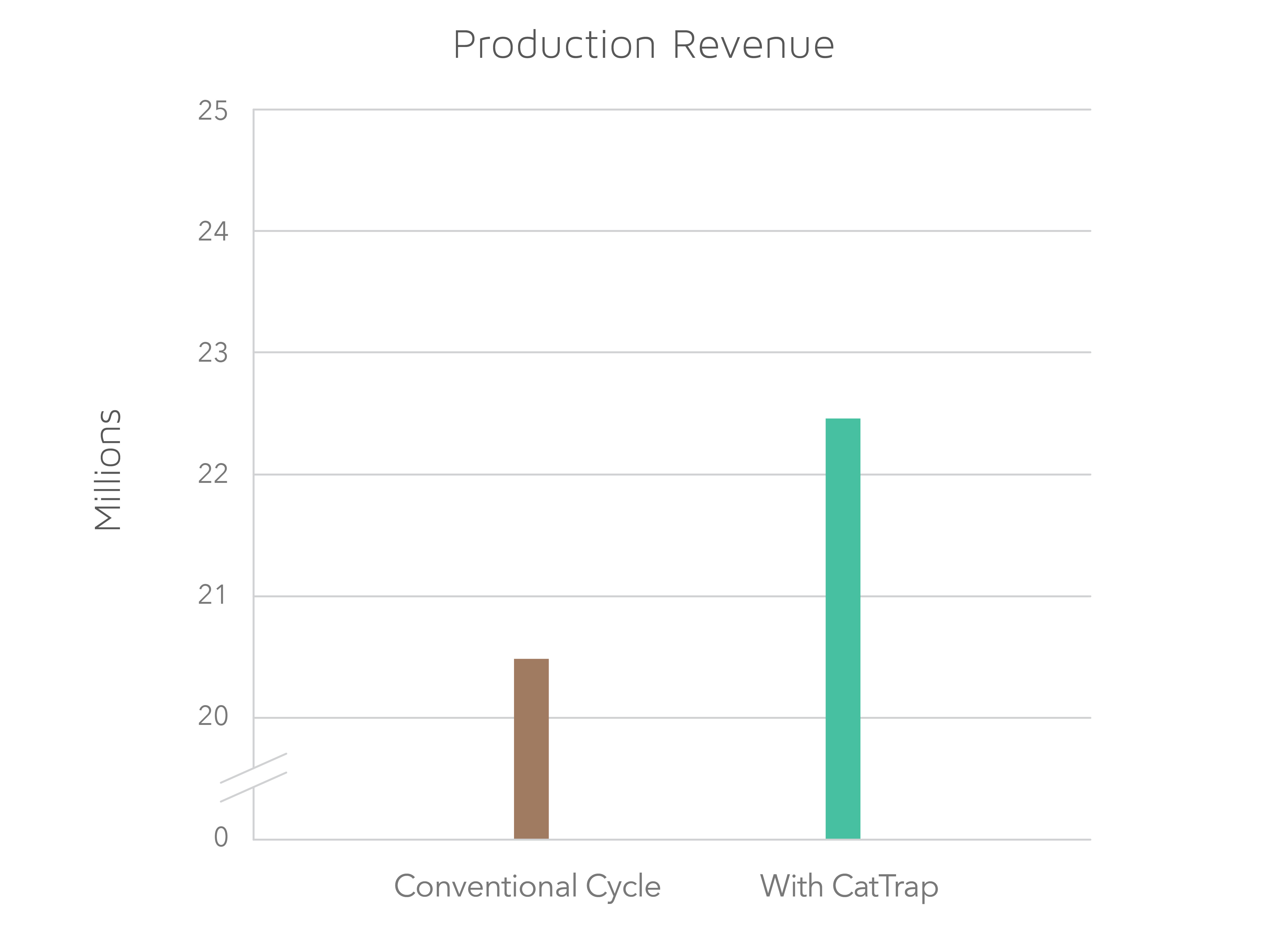

Our strategy more than doubled the unit’s production cycle to 716 days, which made a dramatic impact on their bottom line. Maintenance costs associated with turnarounds—labor, equipment, materials and downtime—were reduced, while the additional production volume generated more revenue. All combined, the annual profitability of the unit increased by $3,869,466.

Increased revenue by nearly $3.9 million.

Enhance your production cycle. Get an analysis.

The shortest path to a healthier bottom line is a comprehensive system evaluation. Get yours.

Enhance your production cycle